New Staircase Installations at The Royal Exchange

Alpine Group has been working on installing three staircases and balustrades at The Royal Exchange in London. Working in such recognisable, important historical venues requires a level of forethought, planning and collaboration that has become a trademark of Alpine’s services and workmanship. In one of the most prestigious of London addresses, several careful considerations were essential to make the job go smoothly and meet client expectations.

The Royal Exchange in London is one of the city’s most prominent historic buildings. The Grade 1 listed building proudly stands tall on the junction where Cornhill and Threadneedle street split, with its impressive eight-column entrance inspired by the Pantheon in Rome. It’s impossible to miss with its imposing, grand entrance.

As well as a sightseeing attraction, today, it is a luxury shopping and dining hub, bustling with independent boutiques, international brands, enticing shoppers to stop for lunch with the scents from fine dining eateries. The building was founded in 1566 by Sir Thomas Gresham as London’s first purpose-built centre for trading stocks.

It has been endorsed by Queen Elizabeth I and Queen Victoria, been burnt down and rebuilt from the Great Fire of London and taken a few stray bombs from the Blitz. It has endured as part of London’s character, despite history’s weathering.

The current building is in fact the third incarnation of The Royal Exchange and its long heritage makes it an iconic structure in The City.

The finer details of architectural appreciation

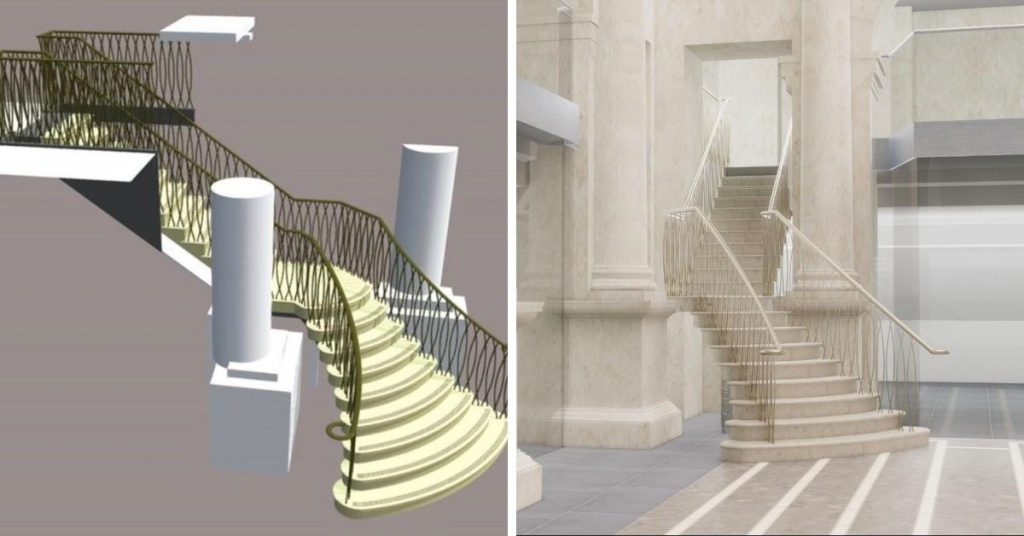

The staircases were situated in the Fortnum & Mason store, a prominent place to both eat and shop, in the cavernous open spaces within the Royal Exchange’s ‘cathedral-like’ interior dimensions.

The Grade 1 listed building proudly stands tall on the junction where Cornhill and Threadneedle street split, with its impressive eight-column entrance inspired by the Pantheon in Rome

For Alpine Group, this rare commission was awarded after a personal referral, which incidentally is where 90% of Alpine’s projects come from. In this case it was the flooring company, Kinorigo that recommended Alpine. They were involved with the flooring side of the project and were already commissioned to re-floor the hall. Kinorigo were asked to collaborate with a reputable staircase company to ensure a continuity of finish and a seamless integration of the stair installation. They needed a collaborative partner which they knew they could work with and trust. Anyone working in construction and architecture will know that trust is invaluable in the trade.

Alpine’s teams have spent years proving to clients and partners they can deliver with meticulous attention to detail and foresight, implicitly understanding the intricacies and demands of each staircase and balustrades installation.

The existing staircase needed to go as a first job, but access had to be maintained at all times, so staged removal had to be planned. The new installation was a complex undertaking with many factors to consider. For one, it had to be installed during the night, to keep the business flowing, and the required finish was a PVD (Physical Vapour Deposition) coating on the metal work. The PVD process can only be applied to stainless steel and working with this material takes a highly specialist skillset that rules out many companies that are not qualified to deliver this service.

Alpine’s philosophy is to always learn and develop with every job taken, as this leads to accumulating a huge amount of experience.

The PVD finish cannot be applied to large areas, so each item had to be broken down into smaller sizes, with hidden joints. However, when it was finally installed it looked like a single item, as required. One of the demanding features of PVD is that it cannot be site repaired, so you only get one chance to get it right. It had to be done off site and there were trial fittings necessary before the coating was applied.

The staircases were structurally designed with CAD software, with considerations for the stonework tolerances, allowing the stone to be cut to Alpine’s templates. On top of this design work, of course safety of the public was paramount, so temporary handrails also had to be installed, whilst the stores were open during the day.

Adapting to the project needs

A great deal of brasswork was needed in the stair nosing, so Alpine made sure there was colour matching continuity with the floor throughout. It goes without saying that the aesthetic is critical in luxury environments. Structurally, there were engineering requirements that needed thought, as the balustrades were required to meet deflection regulations and a bespoke method of proving the design is one of Alpine’s secret methods. Whilst being robust, the balustrades had to be true to design needs, appearing thin and minimalistic. It’s fair to say that the job gave the team plenty of interesting challenges to solve, all to tight deadlines.

Alpine’s philosophy is to always learn and develop with every job taken, as this leads to accumulating a huge amount of experience. Being adaptable, always reaching for the highest standards and making sure collaborations work, are the qualities that Alpine Group exemplifies and working on a venue as iconic as The Royal Exchange was considered a privilege, as much as a project.

Alpine Group were called into this project at a relatively late stage, so a key takeaway was that earlier involvement in the design processes would have created clear efficiencies. This is why Alpine Group offers a no obligation design consultancy to designers and clients to help bring in such efficiencies and cost savings and to ensure the best outcomes and products.

Whilst this was a complicated installation, many of Alpine’s solutions can be relatively straight forward. Alpine specialises in high end clients with high end solutions, delivered by a unique expert team of craftsmen, designers and fitters who live and breathe their jobs in architectural excellence. For more information about Alpine Group services, click here.