Project Review: Nova

Project Partners

- Client: Nova

- Project Manager: Storey

- Main Contractor: Modus

- Status: Complete

Project Overview

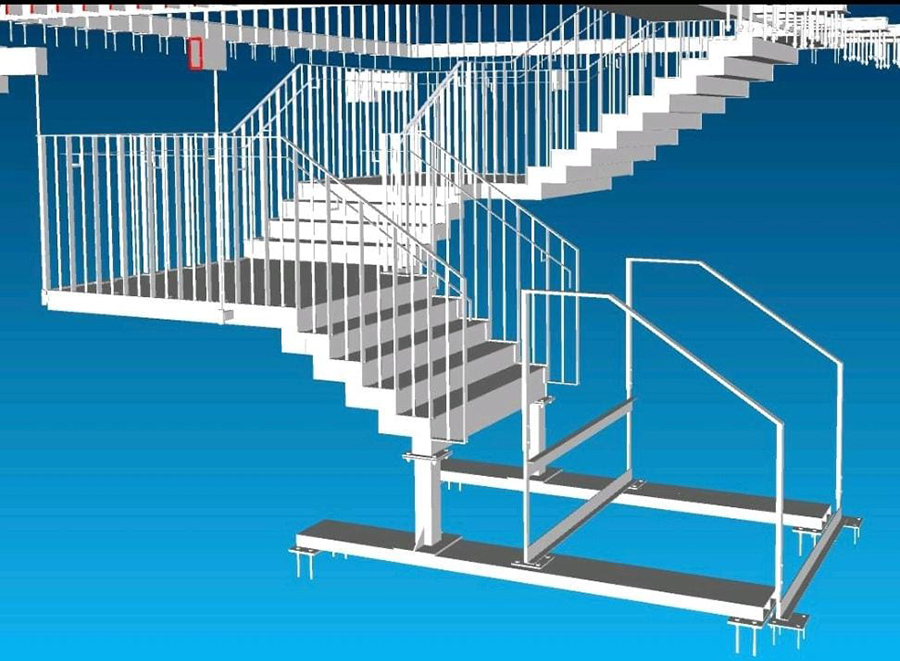

As part of a landmark office fit-out in central London, Alpine was appointed to design, fabricate, and install multiple feature staircases within the Nova development for a global tech client. Situated across multiple upper floors, the staircase was envisioned as a visual and functional centrepiece offering seamless vertical circulation while expressing the high-performance values of the workplace it served.

From the outset, the project demanded exceptional programme control, technical assurance, and aesthetic precision. It was also delivered in a live building under tight timelines, with all works completed to the highest standards of compliance and client expectation.

Understanding the Client’s Vision

Alpine was introduced to the project by Modus, who were seeking a highly competent feature staircase partner capable of delivering to tight deadlines, a complex spec, and with the sensitivity required for a live office environment. The end client, a leading international technology firm, required reassurance around programme certainty, design integration, and budget control.

With a fixed timeline and pressure on early coordination, Modus needed a stair contractor who could take ownership early, de-risk delivery, and work seamlessly with other trades. Our strong sector presence, reputation for technically demanding projects, and track record in fast-turnaround environments helped solidify our position on the job.

Why Alpine Was Appointed

Beyond our experience, Alpine stood out for our ability to move fast on preconstruction requirements, particularly navigating the License to Alter (LTA) process. This involved working closely with structural engineers to satisfy both the landlord and base build team, providing early load calculations, detailed fabrication drawings, and steel design coordination.

Unlike many suppliers, Alpine offers in-house detailing and direct collaboration with seismic-trained engineers, enabling us to shorten lead times and provide assurance around the interface between architectural ambition and structural viability.

Combined with our track record and collaborative mindset, this gave the team confidence that Alpine would not only deliver but do so without surprises.

Navigating Design Complexity

The architectural concept featured a visually crisp, minimal steel stair with a bold sawtooth soffit, continuing cleanly across multiple floor levels. The stair had to look seamless, but perform structurally, balancing aesthetics with technical demands across every junction.

Our team developed a custom-engineered box section solution to carry the required loads while retaining the clean zigzag form beneath. Each tread was formed and welded with extreme accuracy, ensuring the angles of the soffit lined through visually and structurally without deviation.

Additionally, subtle drop rods were integrated to ensure the stair remained rigid and met structural codes and building control requirements, all while remaining visually discreet.

Installation in a Live Environment

The installation presented its own unique challenges. Because the stair travelled continuously across multiple levels, joint placement was tightly constrained and full-flight lengths had to be navigated through a working building.

With limited access to lift shafts and loading zones, every component had to be designed for controlled sectional delivery, then installed during restricted overnight hours to avoid disruption.

Working within a live building also meant tight controls around vibration, dust, and noise. Each section was propped and levelled precisely to the project engineer’s grid and datum’s, then welded and aligned in place. Night shifts were used strategically to keep the project moving while maintaining workplace safety and operational continuity.

Finishes and Coordination

The balustrade design required a golden aesthetic, but brass was ruled out due to installation and fixing constraints. Instead, we worked with the design team to develop a “special affects” painted steel solution allowing for structural fixing and seamless integration with the stair structure. This was focused on a water-based gold sparkle paint to minimise planet impact.

These elements were spray-finished offsite, masked, and delivered in a sequence that allowed for minimal handling and maximum protection.

On the treads and stringers, we worked closely with the timber supplier to coordinate interfaces with millimetre accuracy, ensuring no adjustments were required during installation. All interfaces, steel to timber, baluster to tread, wall to handrail, were handled with care to preserve the design aesthetic.

Outcome & Legacy

What began as a single-phase commission grew into a long-term relationship, with Alpine now supporting further fit-outs for additional flights within the same building. The success of the initial feature staircase, and our ability to deliver under pressure built trust across the team and secured further negotiated work.

The Nova feature staircase stands as a demonstration of what can be achieved when precision, collaboration, and ambition align. It is both an architectural statement and a piece of engineered infrastructure, as beautiful in detail as it is functional in form.

Contact us for a feature staircase on your next project!