Project Review: King & Spalding

Project Partners

- Client: King & Spalding

- Project Manager: Cushman & Wakefield

- Architect: TP Bennett

- Cost Consultant: BAP

- Main Contractor: Overbury

- Status: Complete

Project Overview

Alpine was appointed to deliver a landmark feature staircase for King & Spalding, a leading international law firm, as part of their premium office fit-out at 8 Bishopsgate, one of London’s most prestigious commercial towers. Spanning four floors (Levels 27 to 31), the staircase serves as a central sculptural element, physically connecting key office levels while also reinforcing the visual identity of a global legal brand.

With panoramic skyline views and high-profile usage, the stair needed to deliver exceptional performance across engineering, materiality, and aesthetics, and become a defining experience within the space. The result is a seamless, flowing structure that balances elegance with precision and speaks to the client’s vision of quality, confidence, and connection.

Early Involvement & Strategic Input

Alpine’s engagement began early in the project, through a strategic invitation to contribute to cost planning, design feasibility, and compliance testing. By being involved from the outset, we were able to shape expectations around budget, design intent, and risk, giving the client and project team a grounded path forward from day one.

This proactive, upfront collaboration meant that key constraints and opportunities could be addressed before they became problems, a crucial step on a project where space, sequencing, and technical performance were all under tight pressure.

Turnkey Value & Why Alpine Was Appointed

Alpine was chosen for our ability to deliver a fully integrated, turnkey staircase solution, from structural steel and specialist cladding to GRG soffits, glass, and handrails. Our approach blends off-site manufacturing, BIM-based coordination, and on-site installation into a single, managed workflow. That was critical on a project where precision, programme certainty, and design quality were non-negotiable.

Our digital-first process, including in-factory scanning and model-based coordination, allowed us to start manufacturing while disassembly and site preparation were underway. This overlapped workflow saved valuable time and helped the client maintain programme momentum.

What set us apart beyond our technical expertise, was our ability to de-risk complexity, streamline delivery, and act as a single point of accountability for the entire staircase.

Design Integration & Coordination

As with many contemporary office environments, the staircase at King & Spalding became a focal point for architectural ambition and the convergence of multiple trades.

One of the most demanding aspects was managing differing material tolerances, from structural steel and GRG to timber, glass, and metal finishes. These materials all perform differently and require exacting coordination to meet both aesthetic and structural demands.

Using advanced surveying, tight tolerancing, and clash detection modelling in a BIM environment, we were able to harmonise ceiling details, floor build-ups, fire curtain integration, and MEP services into a clean, resolved geometry.

Midway through the programme, the staircase scope was expanded to include an additional floor. Thanks to our turnkey setup, we rapidly adjusted: strengthening existing steel, modifying the structural aperture, and reworking the build sequence without impacting overall delivery.

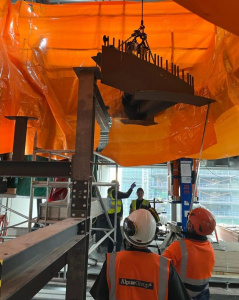

Fabrication & Installation on Site

Installing a helical feature staircase across four high-rise levels came with significant challenges, from restricted access and site logistics to coordinating multi-trade interfaces within a tightly sequenced programme.

Our off-site construction model was central to overcoming these hurdles. Key elements, including GRG soffits, the steel core, timber cladding, and glass balustrades, were pre-fabricated to exact specifications. This not only reduced on-site time and waste but also protected the finishes from environmental and programme risk.

Every trade interface, from fire curtain placements to edge detailing and mechanical fixings, was rehearsed and modelled to ensure perfect execution. And with space at a premium, just-in-time deliveries and coordinated lift access were essential to keeping the programme on track.

Finishes That Elevate the Experience

At this level of fit-out, finishes matter as much as form, and the King & Spalding feature staircase was no exception. The final design incorporated a suite of high-end materials, each carefully chosen for its tactile quality, performance, and visual impact.

- Bespoke timber cladding formed the outer skin, crafted to exceptionally tight tolerances and installed with perfect alignment from floor to floor.

- Glass balustrades featured discreet fixings, with precise junctions that mirrored the rhythm of the timber and maintained visual continuity throughout the ascent.

- Liquid metal handrails added a striking contrast to the natural materials, catching light and providing a refined finish.

- GRG soffits were fabricated off-site and installed with sculptural precision, delivering a crisp underside geometry that tied everything together.

Each of these finishes was the product of careful coordination, digital modelling, and expert delivery. The result was a feature staircase that exceeded client expectations.

Final Outcome & Impact

From start to finish, the King & Spalding staircase was delivered on budget, on time, and to the highest level of specification. There were no surprises in cost, no redesigns midstream, and no compromises on quality. Every component aligned visually, technically, and structurally.

Since its completion, the feature staircase has become a benchmark project, admired not just by the client team but also by visitors and peers. It now stands as a powerful symbol of King & Spalding’s presence in London, and a physical expression of connectivity, ambition, and precision.

Fun Fact

Each floor within 8 Bishops Gate is designed to allow up to 50mm of deflection. The stair design had to allow for this within its calculations; each individual balustrade bar had a bespoke nylon sleeved slip joint to allow for this movement, which at the same time had to be the exact tightness to stay within lateral balustrade load regulations.

Contact us for a feature staircase on your next project!