Project Review: Young V&A

Project Partners

- Client: V&A

- Project Manager: Lockerdell Consulting

- Build Base Architect: De Matos Ryan

- Cost Consultant: (Basebuild & Exhibition Fit-out): Greenway Associates

- Main Contractor: Quinn London, Factory Settings, Florea

- Status: Complete

Introduction

The Young V&A, originally known as the V&A Museum of Childhood, has a rich history dating back to its establishment in 1872. It began as the Bethnal Green Museum, utilising a building originally designed as a temporary structure for the Great Exhibition of 1851 held in Hyde Park.

The museum’s mission shifted over time, and in 1974 it was rebranded as the V&A Museum of Childhood, focusing on the material culture of childhood, including toys, games, clothing, and furniture. Throughout its history, the museum has been a beloved institution in London, known for its nostalgic displays that evoke memories of childhood for visitors of all ages.

The museum underwent a significant £13 million transformation, reopening in July 2023 as Young V&A. This rebranding aimed to create a more dynamic, interactive environment designed specifically for children and young people up to the age of 14.

Alpine was approached by the main contractors (Quinn London) to bring this vision to life with a spectacular feature staircase – the Kaleidoscope Staircase. The project presented a unique and challenging opportunity to create a visually striking and functionally innovative feature for this prestigious museum.

Project Inception and Concept

Alpine were initially approached by several main contractors during the tender stage. They presented us with a complex and visually stunning staircase design, originally conceived using Cross Laminated Timber (CLT).

The design emphasised sustainability and interactivity, featuring mirrors to engage children and create a kaleidoscopic effect as they ascended the staircase.

Establishing a Partnership

After demonstrating our passion for the project alongside our reputation around cost certainty, program surety and guaranteed quality, we were approached by the main contractor, architect, and cost consultant to assit with developing the design.

Following a series of meetings with the principal team and due to the complexities involved, they realised that they needed to work with us in partnership.

Design Adjustment

Although the initial design was well considered, budget constraints required a shift from CLT to alternative materials. The client, through the negotiated partnership, advised us what the budget would be.

We then submitted two proposals for what could be built within that budget and worked with the architects and designers to develop a design in steel for an equally spectacular staircase.

This enabled the architect to build upon that design and factor in their architectural flow and the wants and needs of the museum, which we then had to reverse engineer.

This transition required sensitive handling to align with the budgetary requirements of the project’s donors, without compromising the integrity and vision of the original design.

At this point, we established a Gross Guaranteed Maximum Price (GMP) to proceed with the design-only order, allowing us to fully leverage our design team’s expertise to achieve the best value for the project, again reinforcing that cost certainty and program surety.

Engineering Expertise and Aesthetic Integration

Our engineering expertise and forward-thinking design capabilities were crucial in winning the project. The primary challenge was to structurally support the staircase while maintaining its aesthetic appeal.

Multiple design iterations were necessary to balance structural integrity with visual elegance, ultimately finding a solution that met both criteria within the budget constraints.

Fabrication and Installation Challenges

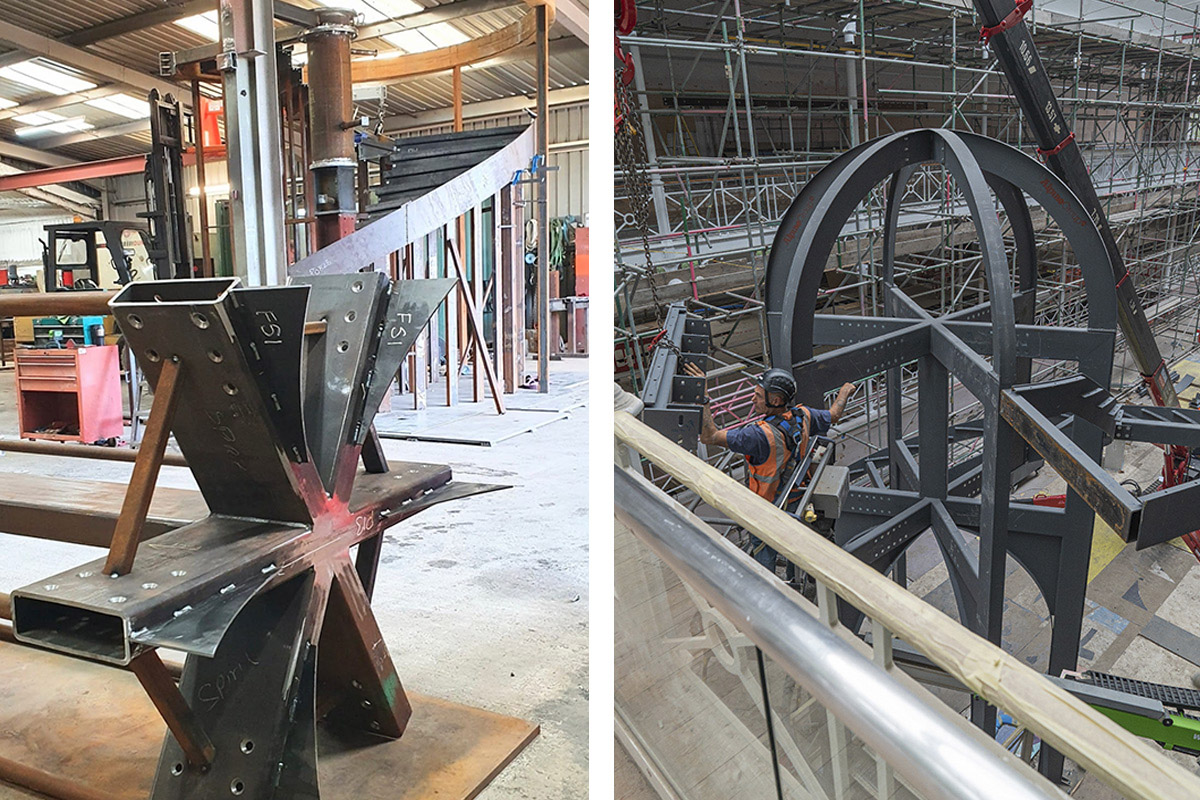

The fabrication and installation phases presented significant challenges, particularly in transporting large components without damaging the existing mosaic flooring of the heritage building. We collaborated closely with the main contractor to break down the components into manageable weights and used specially designed “material handlers” to navigate the space. Strategic planning ensured that point loadings did not compromise the floor, and careful placement of cranes prevented damage to the building.

Hidden Connections and Structural Flow

Maintaining the visual flow of the staircase required innovative solutions for hidden connections and continuous treads. Close collaboration with local authorities and building control allowed us to implement a special compensation strategy, ensuring a seamless design without the need for rest landings.

Sensitive Fabrication and Finishes

Regular visits from the design and client teams to our factory facilitated close monitoring and quality assurance during fabrication. Our proximity to London was advantageous, enabling frequent consultations and adjustments. The final staircase featured timber treads, a sleek black handrail, and a structurally sound centre crucifix, designed to support the kaleidoscope mirrors and achieve a smooth, integrated appearance.

A Royal Inauguration

The project was completed within a strict timeline, driven by a predetermined launch date. Successful collaboration between architects, engineers, contractor and cost consultants was critical in meeting this deadline.

The completed Kaleidoscope Staircase has received overwhelmingly positive feedback. Visitors have been captivated by its design, often becoming a focal point of their museum experience. The project has significantly increased footfall, breaking attendance records for the museum (750,000 in the first year).

To all of the team’s pride, the staircase was inaugurated by Catherine, Princess of Wales and the director of the Victoria and Albert Museum, further highlighting its cultural significance.

The success of the Kaleidoscope Staircase project is a testament to the collaborative efforts of all involved parties. We extend our gratitude to the architects, engineers, cost consultants, and the entire project team for their dedication and hard work.

Contact us for a feature staircase on your next project!