Project Review: The Met Building

Project Partners

- Client: The Met Building / Lazari Investments Ltd

- Architect: : Forme UK

- Main Contractor: Vision Arch / Vert Projects

- Quantity Surveyor: N/A

- Status: Complete

Introduction

One of our recent projects was to design, fabricate and install a feature staircase at the renowned Met Building in London. Lazari Investments appointed Forme UK architects to refresh and enhance the identity and standard of The Met Building to meet the expectations of contemporary high-profile tenants.

As part of the overall vision, Forme UK was seeking to add an external steel staircase that connected the service yard to the basement to provide access to a new cycle storage area.

In keeping with a design direction that was brighter and more contemporary, the feature staircase required a significant amount of glass façade work.

Background and Context

Vision Arch, a Specialist Façade Contractor, was invited to tender for the project. It required two key elements, their glass expertise, and a feature staircase that would become a centrepiece of the architectural design.

Understanding the complexity and the integrated nature of the staircase within the glasswork, they were looking for a real partnership, more than just a fabricator.

Initial Consultation

Our reputation as specialists who go beyond mere fabrication to offer comprehensive turnkey solutions was a key factor in Vision Arch’s decision to approach us.

Our ability to work within precise tolerances, coordinate seamlessly on drawings, and embody a genuine partnership ethos set us apart.

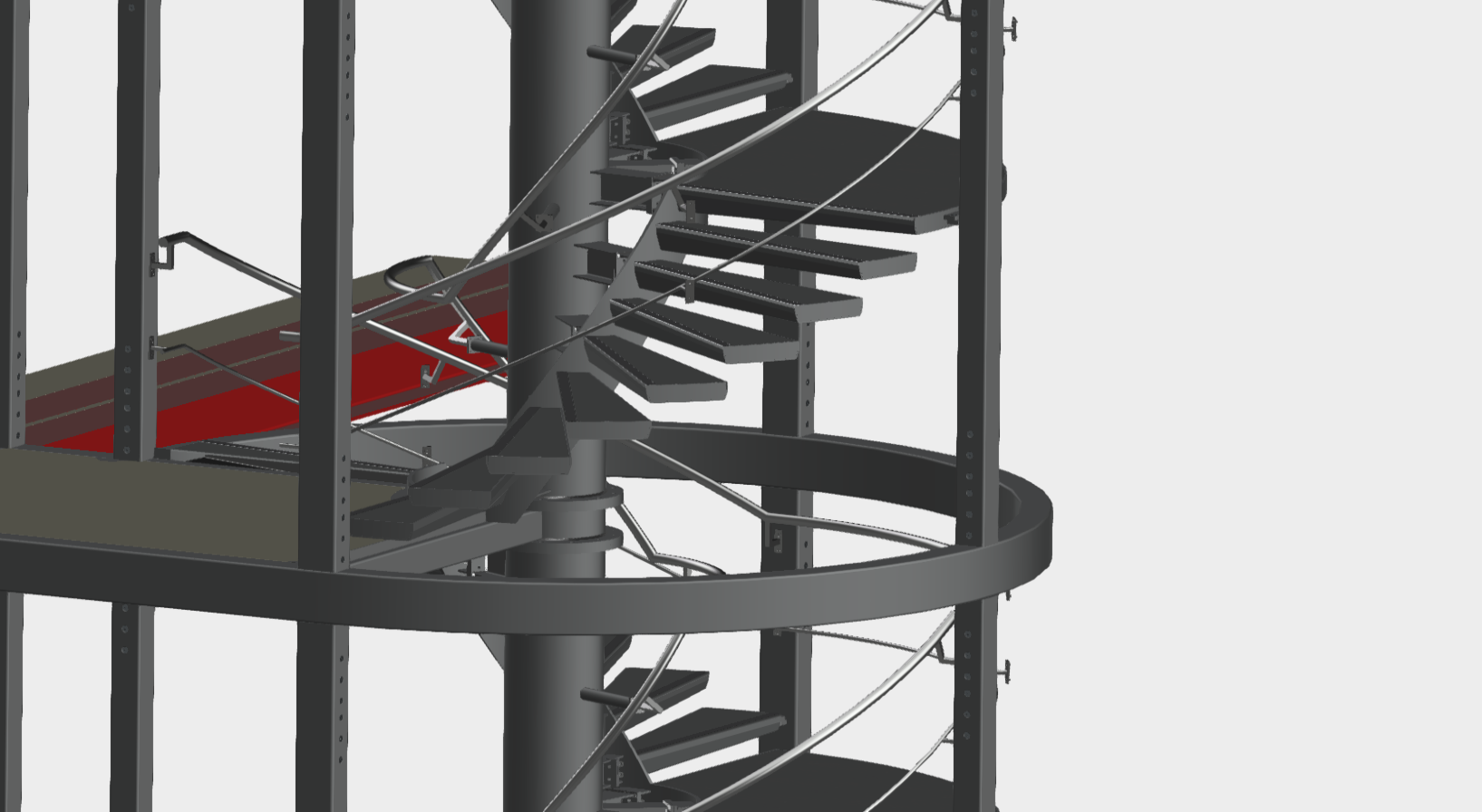

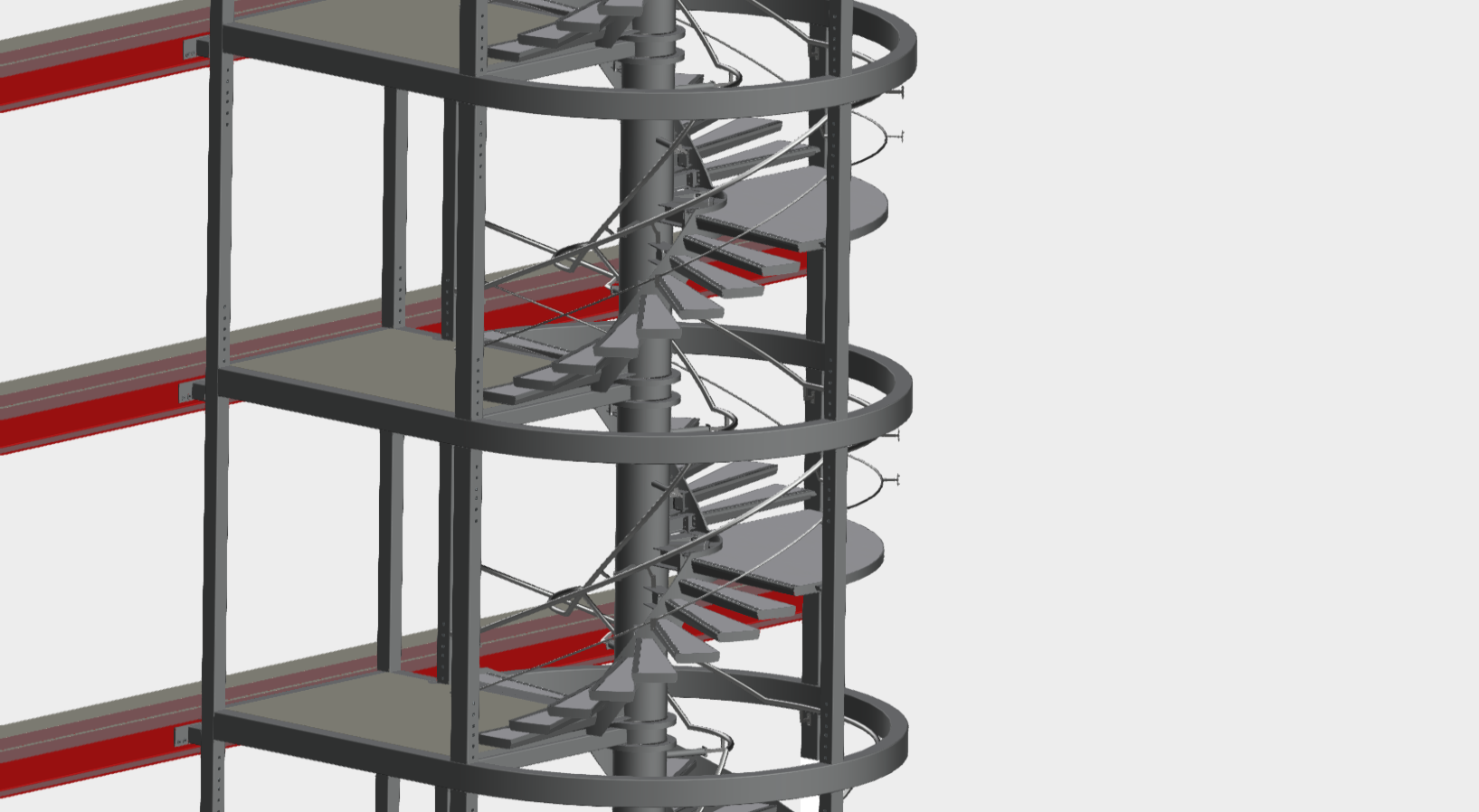

At the tender stage, we recognised the limitations of only visualising the project from existing 2D drawings. With this in mind, we invested in creating 3D models and renders to communicate our solution in the highest fidelity possible.

This proactive approach clarified the project’s scope for our client and significantly contributed to winning the tender itself by showcasing an unparalleled vision for the staircase component.

Design & Fabrication

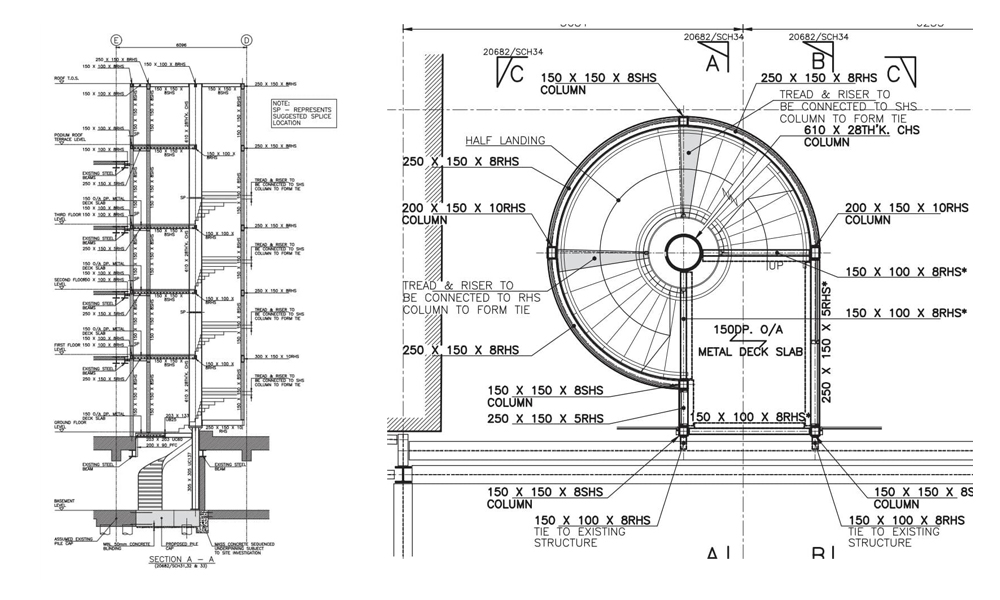

The project featured intricate design and fabrication challenges that we were keen to take on. It required close collaboration with Vision Arch, especially in integrating the staircase with the façade, thermal break and glazing systems.

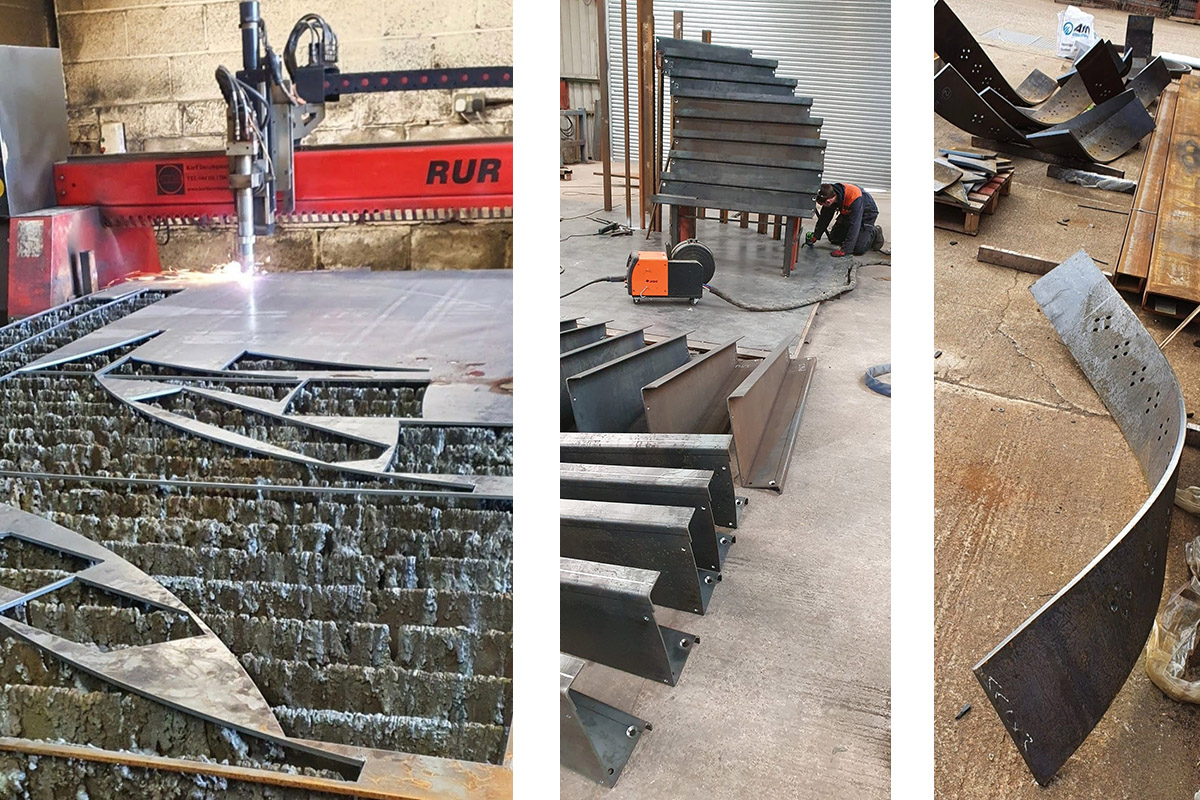

The structural requirements demanded large steel members which had to be formed with exceptional precision to fit the glass cladding. Our team employed very specific techniques to prevent creasing and buckling during this process, ensuring seamless integration.

The manufacturing approach was to produce and deliver as large a members/sections as possible to ensure there was no loss of form or accuracy. This also reduced time on site and our carbon footprint, driving down costs.

The fabrication of bespoke staircase treads required special tooling and fabrication techniques to achieve the desired detail and bespoke tread shape, alongside the integration of wiring and lighting systems within the treads and handrails. This was important as the treads were free-standing with no end supports.

Installation

Logistically, the installation posed its own set of challenges, including the need for specialised transport to navigate under motorway bridges and comply with out-of-hours road closures for pedestrian management.

The coordination of cranage to position the large staircase elements accurately was crucial for allowing subsequent glass fittings. Additionally, accommodating the variance in finished floor heights across multiple floors required meticulous planning and execution.

Delivering on our promise

The Met Building project stands as a testament to our capability to fabricate and collaborate with absolute precision on complex architectural designs.

Our investment in 3D modelling and rendering at the tender stage emphasised our commitment to supporting our clients in winning and successfully delivering on significant projects.

This project demonstrates our position as leaders in feature staircase manufacturing and highlights the benefits of a turnkey solution. Our clients only need to work with one provider across design, concept, manufacturing, installation and finishing.

“Having Alpine on board as one of our specialist sub-contractors on the MET Building was key to the overall success of the project. Dealing with their team; right through from the initial Sales enquiry with Trevor Barry to the Installation Manager – Craig Singleton, was a pleasure.

Their knowledge of spiral staircases is second to none.” Eddie Wells, Managing Director – Vision ARCH – Vision ARCH Case Study

Contact us for a feature staircase on your next project!