Project Review: Alpha Tauri Red Bull Formula 1 Team Staircase

Project Partners

- Client: Alpha Tauri / Red Bull

- Architect: : Rigby & Rigby

- Main Contractor: Rigby & Rigby

- Quantity Surveyor: N/A

- Status: Complete

Introduction

Rigby & Rigby were looking for a staircase partner for their client, the Formula 1 team, Alpha Tauri Red Bull. They required an exceptional spiral staircase for their flagship store in London, on Brompton Road.

Alpine Group UK was the perfect partner as a turnkey specialist staircase design consultancy that could meet the complexities of the project.

Background and Context

Rigby & Rigby introduced Alpine to the challenge that their client was facing. How to build a spiral staircase with a glass central shaft as its supporting structure, along with all the other specialist finishes that go along with a feature staircase.

As leading specialists in staircase design, manufacture and installation, we were invited to meet directly with the client to look at their concept and present what we had to offer.

Initial Consultation

We met with the Alpha Tauri Red Bull team to understand their concept in more detail. A spiral staircase with a glass central shaft as its supporting structure, including lighting and a central atmospheric chamber for a real-life waterproof testing experience of the garments for sale.

This is the type of complex project we enjoy at Alpine and one that perfectly fits our approach to design. We were only too glad to assist Rigby & Rigby with their design.

For any staircase project, our approach begins from a reverse engineering perspective, first understanding what the staircase needs to look like, and then working out how to build it.

We only propose what we know is possible to build, and in a way that meets all technical load and safety requirements.

Design Concept Presentation

We prepared the Alpine solution and presented this directly to Rigby & Rigby and Alpha Tauri Red Bull.

As you can see from the image, the rendering we presented is highly complex and would be representative of the end result. To achieve this, we ran fully detailed light path tracing, a rendering technique that simulates the way light interacts with objects and how light rays bounce around in a scene.

In this video, you can see the light bars underneath the staircase, showing exactly how the light would reflect off that chamber as you walk around it.

This level of fidelity is invaluable for clients who need to get a true feel of the end product at concept stage. It’s part of the service we provide at Alpine to help our clients understand the reality of what their staircase will look like.

Having demonstrated our approach and reviewed our past projects, we were thrilled to be awarded the project.

Concept Features Gallery

The Complexities of Staircase Design and Manufacture

As a main feature, our client wanted the staircase stringer to look like a complete seamless sweep, all the way down, wrapping around the glass chamber which provides the structural integrity of the staircase.

NOTE: It is very difficult to develop a helical staircase with a seamless continuous flow that conforms with building regulations. There almost always has to be a half-landing that breaks the flow.

So with the help of the client and after a number of meetings, we increased the width of the stringer, and with a bespoke flow in the pitch, we minimised the half-landing disruption in the flow.

A Full Turnkey Solution

First and foremost, Alpine are staircase designers and consultants, providing a full turnkey solution where we facilitate all the finite elements, engineering, manufacturing, welding and finishing, all under one roof.

As specialists in stair design, we take our clients on a journey with us, through upfront design, development, renderings, co-ordinating with other trades, turnkey finishes and cost planning. We make sure the specification is buildable, practical and affordable.

We also help our clients with the build programme, ensuring it interfaces with the principal programme, always looking for creative ways to overlap trades to bring time savings. We also make sure the cost programme and specifications are managed the whole way through.

This is so important for getting every aspect of staircase design, manufacture and installation absolutely right. And in this project, even down to the glass specification itself.

Client Benefit – No Pain Points

For Rigby & Rigby and Alpha Tauri Red Bull, this approach meant they had a full turnkey solution from concept through to finished installed staircase, all under one roof, in-house. There were no other contractors they had to work with, just Alpine.

Typically the pain points around these types of projects are that a client can end up with a separate fabricator who they have to take the design to. The fabricator would do their part, then a lighting specialist would need to be found to do their part, and the same for someone to do the finishing. This is where significant misalignment between companies can happen.

As Alpine come into a project as a turnkey solution, that level of risk is mitigated completely.

Where projects can really fall down is in the finishing, and finishing was absolutely critical for our client. Being a Forumla One team, it had to have a perfect liquid metal finish. To achieve this, we needed to understand how the lighting interacted with the staircase, the glass and the paint finish itself, so we could build a staircase that perfectly matched that liquid metal specification, and that’s exactly what we did.

An Unplanned Pit Stop

Changes in projects can happen, and depending on what those are, they can really challenge everyone involved. As an agile company with a full turnkey solution, Alpine are adept at rising to unplanned changes.

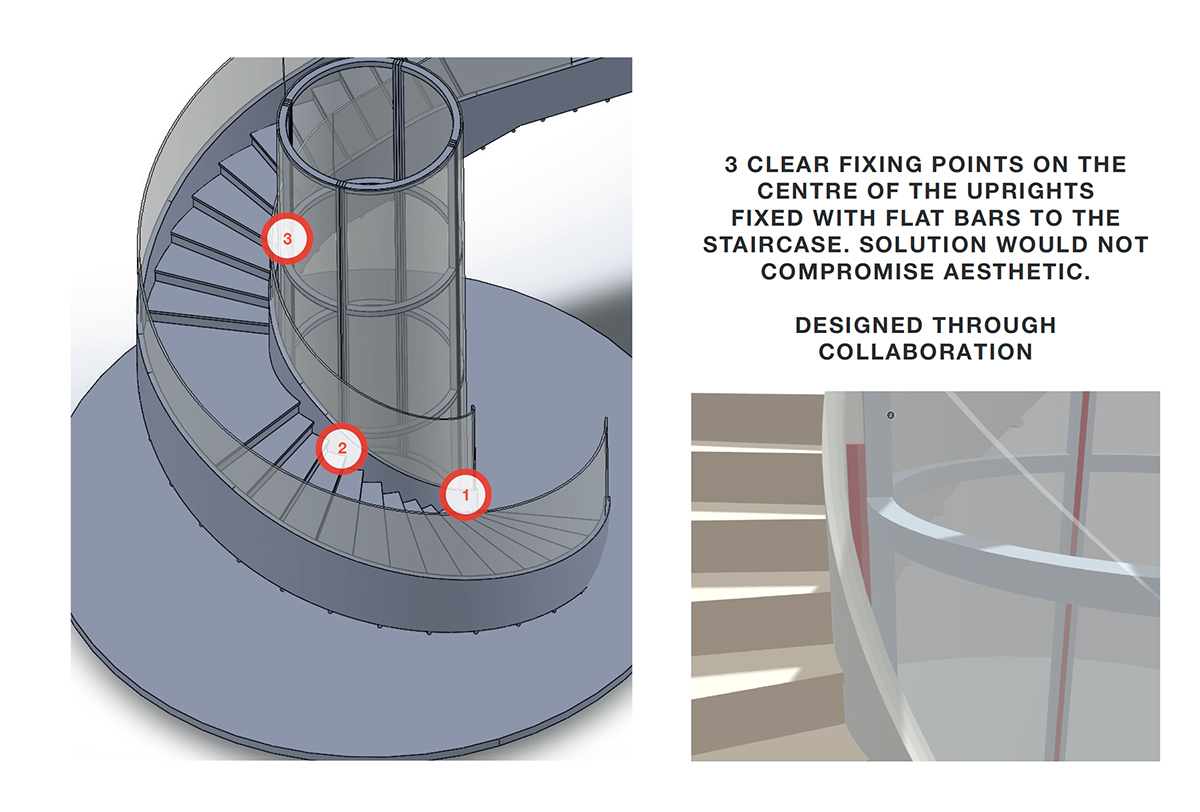

In this case, the client decided the central atmospheric chamber was not going to be feasible for them in reality, taking into account humidity and general moisture management. As a result of removing this shaft, the staircase lost its central supporting structure, a seismic change!

This however was not a problem, as we are actually experts in seismic engineering.

Seismic Engineering

At Alpine as well as being staircase designers and consultants, we are also seismic engineers who are trained in the principles of reverberation. As trained professionals, we are responsible for ensuring that staircases are structurally sound and capable of withstanding seismic events, such as earthquakes.

It requires a deep understanding of dynamic forces and the interaction between a staircase and the building it serves during seismic activity.

This relates to all levels of reverberation, and through differing frequencies. As such, we conduct live modelling that simulates reverberation, movement and transfer of loads to ensure the staircase is absolutely safe and secure.

This also helps when there is a change of plan, we can apply all of our live modelling to new design solutions and make sure that what exists in concept works in reality.

With this staircase, and indeed with most staircases, there always seems to be a lack of existing structure to fix to. As a result, we find raft steelwork, bespoke trimming of steel, back propping and hidden structural hangers, commonplace.

As this staircase lacked a supported structure at the top and bottom, fixing had to be extremely well designed. Not only did the basement need bespoke structural works for the load, so did the new mezzanine on first floor to take the loads.

Installation

When it came to installation, our team were able to install all elements without any issues. This comes down to well-oiled logistical planning and execution. Every installation comes with its own unique challenges, and the handling of large heavy bespoke items is not for the faint-hearted.

At Alpine, this is a daily occurrence for our trained teams with:

- Lift Plans

- Method Statements

- Traffic Management

- Back Propping

- Temporary Works

- Floor Bearing Plates

- And more…

This enables us to consistently deliver the quality safely and on time.

Across the finishing line

Our client was thrilled with the results, and the grand opening day was a huge success.

Post-race Review

This project really serves to highlight the benefits of a turnkey solution, where the client only has to work with one provider who specialises in these bespoke deliveries, across design, concept, manufacturing, installation and finishing.

So many typical pain points disappear and the risks are mitigated with full co-ordination and value engineering.

If you’re ever near Harrods, just walk down the road and take a look at the Alpha Tauri Red Bull showroom, the staircase centrepiece awaits you!

Contact us for a feature staircase on your next project!