Alpine Group Make the Impossible Possible in London Property

There are moments at Alpine when a good set of heads put together can take what looks like an insurmountable technical problem and think outside the box to achieve something extraordinary, that defies limitations. With a staircase design for a luxury property in Belgravia in London, that is exactly what happened.

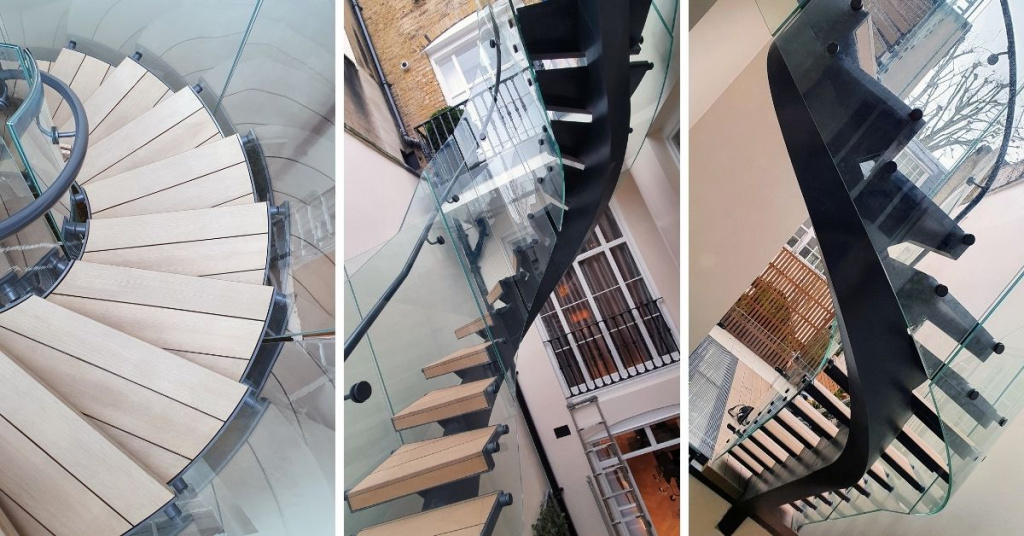

The high-end property had challenging dimensions to accommodate a vision for a staircase, one where a narrow space between two walls could hold helical stairs that curled sharply to a higher outside terrace. The angles needed, the radius needed, to accommodate the glass elements of the build meant that many a company would simply shake their head and say, ‘nice idea but this is impossible to create with these materials and in this space.’ In contrast, Alpine Group loves a technical challenge. The team paused, broke the problem down and with a heritage of solutions that make the impossible possible, decided they would take on the project and make it happen.

Taking a load off

The initial challenge that presented itself was that the stairs had very limited support areas where loadings could be fed back into the existing structure. The limited existing loading capacity meant the Alpine Group team needed to work very closely with the structural engineers of the existing building and surrounding structure. The result of this collaboration was that Alpine was able to add extra structural members to increase the capacity loading as required. This was just the first challenge.

The ‘wow’ factor was worth it. Without a doubt, other firms would not take this task on. The beautiful, contemporary staircase appears to hang in the narrow space and looks almost impossible.

Solving challenges, step by step

The design envisaged a large central spine feature stairs. No standard structural members could be bent to the radius required. The central column had to be hand-forged and formed and split into four separate plates. This pushed the capacity of the steel to its limits. You won’t likely see many, if any staircases quite like this one. That wasn’t the end of the challenges, however. The most interesting problem was yet to come.

A third restraint was that the internal radius was below the limits of the minimal possible radius that structural glass could be formed to. This was a physics bending moment in the design! The way this was tackled is a bit of an Alpine secret, nevertheless, the thresholds for the bend were overcome. This is a challenge that would scare off many in the trade, and the Alpine team were proud to dig deep to find the solutions.

Worth it for the ‘wow’

With all the technical conundrums overcome, the staircase needed to be for want of a better word ‘shoehorned’ into position in a tight space. The ‘wow’ factor was worth it. Without a doubt, other firms would not take this task on. The beautiful, contemporary staircase appears to hang in the narrow space and looks almost impossible.

The confidence of Alpine’s team can be seen in their technical excellence and adaptability to design challenges. Many architectural visions come from a sketch to the engineers and it’s true that not everything drawn can be made but this time, the combined knowledge, expertise and intelligence of the whole team created a staircase masterpiece in the heart of a world-famous address in London.

If you have a staircase design that needs expertise and care, contact the friendly team at Alpine Group and we can help you turn the drawings into beautiful stairs.